You are here: Home : Products : AMI Pipeline Inspection Systems : Crawlers : Authorised Distributors : Pipe Profiling Sonar Systems : The SP2512 Pipe Profiling Sonar

Features include:

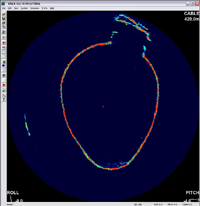

- Real Time continuous scanning over a full 360°in 1 second

- Windows user-friendly software with USB hardware minimises training time

- Direct capture to Hard Disk for high resolution image save and restore

- Dual tracking cursor for accurate on-screen measurements

- 360º Internal Pitch and Roll sensors

- Quadrature and compatible cable counter interfaces built in

- 500m cable drive as standard, fibre-optic system optional

- Automatic profile detection and output in ASCII format for import into third party 3D modelling software

The Model 2512 Pipe Profiling Sonar provides an acoustic method for profiling the interiors of liquid filled pipes or boreholes. This method does not require draining of the pipes as with camera surveys and provides accurate quantified data which can not be obtained from a camera display alone.

The equipment comprises of an underwater Scanning Unit (which may be skid, float, tractor or ROV mounted) and a compact USB interface Unit. To complete the system a "Windows" P.C. with a USB port is required to run the 2512 system software.

The Scanning Unit is a rugged stainless steel cylinder with a pressure balanced polyurethane transducer housing at one end, and the umbilical cable connector at the other. The standard Scanning Unit is rated at 100m operational depth. Two lead-acid batteries could be used to power the Scanning Unit together with a notebook P.C. for a completely portable solution. Internal Pitch and Roll sensors display, in analogue and digital form, the orientation of the sonar in the pipe.

The USB Interface Unit connects to either a USB1.1 or USB2.0 port on a host P.C. running under the "Windows" operating system. (Win'98 upwards is supported). The USB Interface has inputs for a cable payout encoder so that the distance travelled may be displayed to 0.1m resolution allowing accurate determination of where flaws exist in the pipe relative to the deployment position. The USB Interface is self-powered from the P.C.

The resolution and update speed of the Model 2512 Pipe Profiling Sonar is second to none in the field of mechanically scanned sonar’s. The 2MHz acoustic signal is amplified and logarithmically compressed prior to being digitised by a Flash A/D converter.

The angular resolution of the system is 0.9° which gives 400 sectors per revolution. For each sector the data is over sampled and peak detected to arrive at 250 range cells.

The digitally generated graphics display uses 256 colours to represent the signal amplitude. At a minimum full-scale range of 125mm this gives a range resolution of 0.5mm and at 2m range the resolution is 8mm.

The acoustic beamwidth of 1.8° ensures that the finest detail from the pipe surface is recorded. Pitch and Roll sensors inside the scanner record the attitude of the sonar to a resolution of 0.1°.

The sonar has been engineered for extended operations in hostile environments. The transducer and drive motor are totally enclosed in an oil-filled pressure balanced housing which is hermetically sealed from the stainless steel electronics pod.

The system has many applications other than inside pipes where short range high precision measurements are required with a rapid screen update.

Data View

High resolution image capture

AC-DC Power Supply with USB Interface Unit

Stand-alone USB Interface Uni

Model 2512 Pipe Profiling System

Software Features:

Display Modes: Polar - full 360º coverage

Sector - 30º to 270º arc width at 30º to 330º centre angles in 30º steps Range settings (mm): 125, 187, 250, 375, 500, 750, 1000, 1500, 2000 Range settings (in): 5, 7.5, 10, 15, 20, 30, 40, 60, 80 Range Resolution: 1/250 of full scale range eg. 0.5mm at 125mm Minimum Range: 50mm Angular Resolution: 0.9 degrees Tx Pulse Length: Variable 4usec to 20usec Display Resolution: 400 sectors of 250 range cells Colour Control: 8bit multiple palettes with min, max and step control to optimise

dynamic range ASCLL Output: NMEA style profile string via RS232 Autostart: May be used autonomously without keyboard, mouse or display for remote data capture when it is not possible to use a cable Viewer Program: A separate viewer program is available to allow clients to post

process and print stored images Operating System: Windows '98, ME, 2000, NT, XP

Underwater unit:

Acoustic Frequency: 2MHz Beam Width: 1.8 degrees conical Receiver: Bandwidth: 500kHz Pitch/Roll Sensors: Micromachined accelerometers resolution 0.1 degrees Power Requirements: +14VDC at 1A maximum Overall Length: 178mm Diameter: 50mm Finish: Stainless Steel 316 with polyurethane transducer housing Operating Depth: 100m Operating Temp: 0 to + 40 degrees C Storage Temp: -20 to +70 degrees C Weight in Water: 0.4 kg Weight in Air: 0.75 kg

USB Interface

Protocols: USB 1.1 and USB 2.0 Cable Payout Input: +5V Quadrature Power Requirements: +5VDC at 200mA typical (selfpowered from USB port) Dimensions: Width: 110mm

Depth: 165mm

Height: 35m

Options Include:

- AC to DC power Supply with USB Interface Unit

- Cable drum with slip rings (various lengths)

- Fibre-optic drive modules for extended cable length

Cameras

Cameras Camera Accessories

Camera Accessories Pushrods

Pushrods Crawlers

Crawlers Cable Drums

Cable Drums Camera Control Consoles

Camera Control Consoles Toughbook

Toughbook Customised Vehicles

Customised Vehicles Spares

Spares Multi Purpose Cables

Multi Purpose Cables VS 200 Sonar

VS 200 Sonar